Analysis of three kinds of temperature control technology of battery PACK thermal management system

The temperature environment in the battery PACK (PACK) has a great impact on the reliability, life and performance of the battery cell, so it is especially important to maintain the temperature in the pack within a certain temperature range. This is mainly through cooling and heating to achieve, here we air cooling, liquid cooling, direct cooling three kinds of cooling methods are briefly introduced.

Air cooling

Air cooling is a heat dissipation method that uses low temperature air as the medium and the convection of heat to reduce the temperature of the battery, which is divided into natural cooling and forced cooling (using fans, etc.). The technology uses natural wind or fan, with the evaporator of the car to cool the battery, the system structure is simple, easy to maintain, and is widely used in early electric passenger cars.

Liquid cooling

Liquid cooling technology takes away the heat generated by the battery and reduces the temperature of the battery through liquid convection heat transfer. The liquid medium has high heat transfer coefficient, large heat capacity and fast cooling speed, which has significant effect on reducing the maximum temperature and improving the consistency of the temperature field of the battery pack. At the same time, the volume of the thermal management system is also relatively small. The form of the liquid cooling system is more flexible: the battery cell or module can be immersed in a liquid, or the cooling channel can be arranged between the battery modules, or the cooling plate can be used at the bottom of the battery. When the battery is in direct contact with the liquid, the liquid must be insulated (such as mineral oil) to avoid short circuit. At the same time, the air tightness of the liquid cooling system is also higher. In addition, it is mechanical strength, vibration resistance, and life requirements. Generally, high and low temperature coolant testing machines are used.

direct-cooling

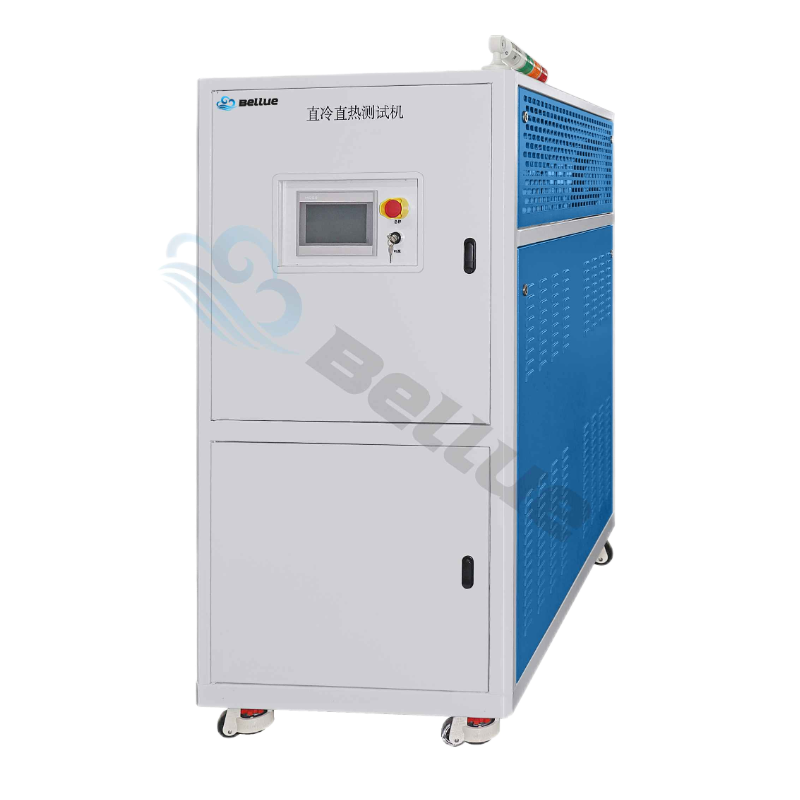

Direct cooling (refrigerant direct cooling) : The use of refrigerant (R134a, etc.) evaporation latent heat principle in the vehicle or battery system to establish an air conditioning system, the evaporator of the air conditioning system installed in the battery system, the refrigerant evaporates in the evaporator and quickly and efficiently take away the heat of the battery system, from the completion of the battery system cooling operations. Generally, direct cold and direct heat testing machines are used.

The advantages of direct indifference are:

(a) Cooling efficiency is 3 to 4 times higher than liquid cooling;

(b) better meet fast charge requirements;

(c) Compact structure;

(d) Potential cost reductions;

(e) The flow of glycol solution inside the battery housing is avoided.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions