The principle of battery pack liquid cooling test machine is revealed

With the vigorous development of the new energy vehicle market, battery pack as one of its core components, its performance and safety have attracted much attention. In order to ensure the stability and reliability of the battery pack under various extreme conditions, the battery pack liquid cooling testing machine came into being. This article will give you an in-depth analysis of the working principle of the battery pack liquid cooled test machine, and take you to appreciate the charm of this technology.

First, the basic concept of battery pack liquid cooling test machine

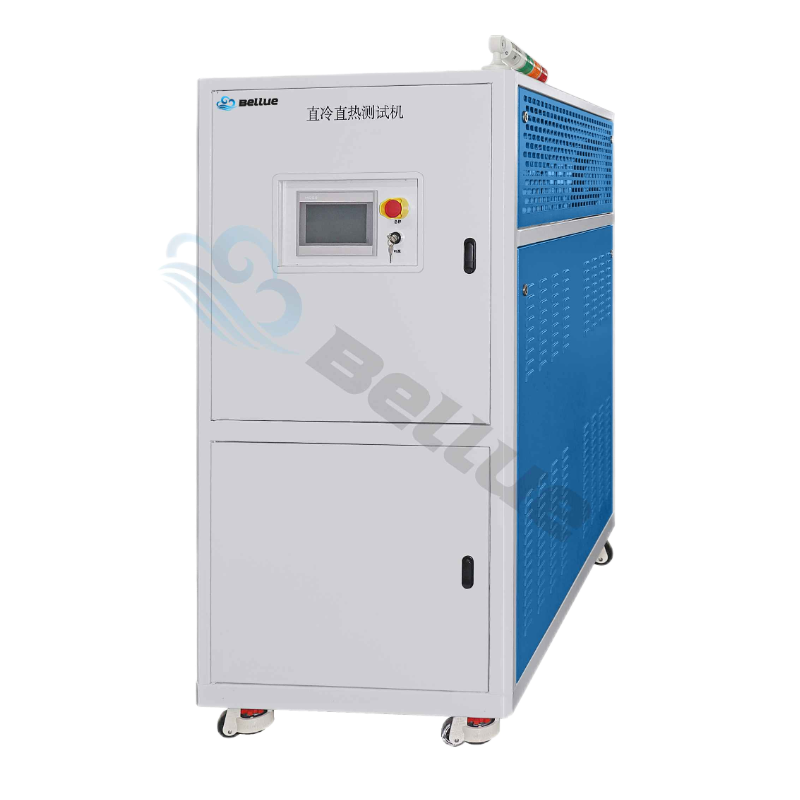

The battery pack liquid cooling test machine is a device that simulates the actual working environment of the battery pack. The battery pack is cooled by the liquid cooling system to test its performance and safety under the conditions of high temperature, low temperature and high load. The device can simulate various extreme situations that the battery pack may encounter in actual use, providing strong support for the development and production of the battery pack.

Second, the working principle of the liquid cooling system

The liquid cooling system is the core part of the battery pack liquid cooling test machine, and its working principle mainly includes two aspects: circulation cooling and temperature control.

Circulation cooling: The liquid cooling system circulates the coolant to the heat dissipation part of the battery pack through the circulation pump, absorbs the heat generated by the battery pack, and then takes the heat to the radiator for heat dissipation, so as to achieve the cooling of the battery pack. This type of cyclic cooling ensures that the battery pack always maintains a stable temperature during continuous high load operation.

Temperature control: The liquid cooling system is also equipped with a precise temperature control system, which can precisely adjust the temperature of the coolant according to the test requirements. The temperature sensor monitors the temperature of the battery pack in real time, and the temperature control system can adjust the circulation speed and temperature of the coolant in time to ensure that the battery pack works within the set temperature range.

Third, the application of battery pack liquid cooling test machine

Battery pack liquid cooling testing machine has a wide range of applications in the development and production of new energy vehicles. It can simulate various extreme conditions of the battery pack in actual use, such as high temperature exposure, low temperature freezing, continuous climbing, etc., to test the performance and safety of the battery pack. Through these tests, developers can find possible problems and hidden dangers in the battery pack, and then optimize and improve it to improve the performance and safety of the battery pack.

In addition, the battery pack liquid cooling test machine can also be used for battery pack life test. By simulating the charge and discharge cycle and temperature change of the battery pack in actual use, the life and performance attenuation of the battery pack can be predicted, which provides a scientific basis for the maintenance and replacement of the battery pack.

Iv. Conclusion

With its precise temperature control and simulation capabilities, the battery pack liquid cooling test machine provides strong support for the development and production of new energy vehicle battery packs. Through in-depth understanding of its working principle and application scenarios, we can better use this technology to promote the sustainable development and innovation of the new energy vehicle industry. With the continuous progress of science and technology and the increasing expansion of the market, it is expected that the battery pack liquid cooled test machine can play a greater role in the future and contribute more to the popularization and promotion of new energy vehicles.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions