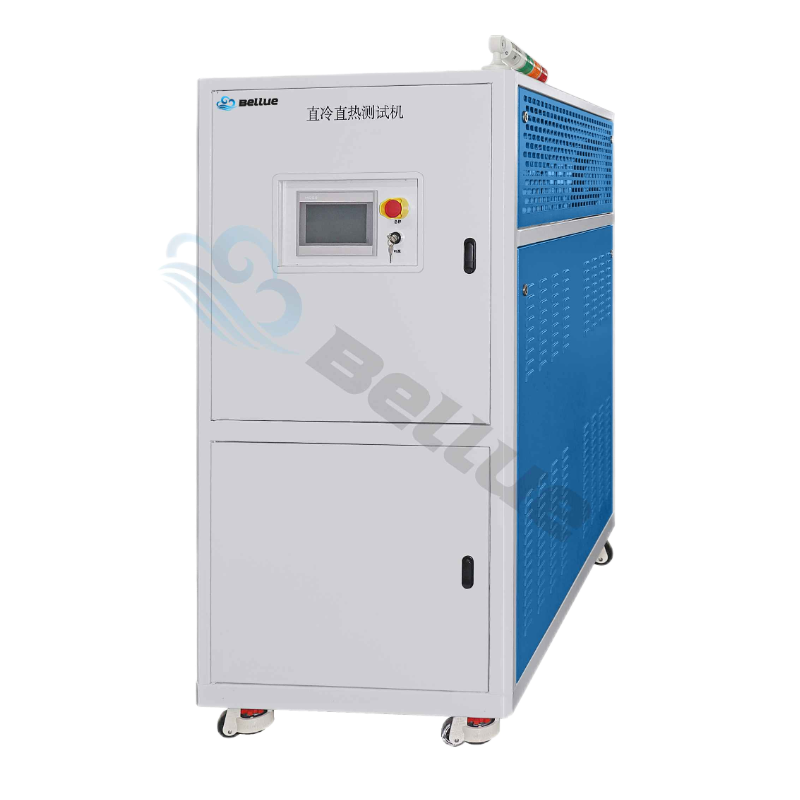

New energy vehicle power battery direct cooling direct heat test machine application

With the vigorous development of the new energy vehicle market, the power battery as its core component, its performance and safety are directly related to the vehicle's driving range, charging speed and service life. In this context, the cooling and heating technology of power batteries is particularly important. Today, we will focus on the application of the new energy vehicle power battery direct-cold direct-heat test machine and the revolutionary changes it has brought.

Direct-cold direct-heat technology, as the name suggests, is a technology that can directly cool and heat the power battery. Traditional battery thermal management systems mostly use air-cooled or liquid-cooled methods, but these methods often have problems such as uneven heat dissipation and low efficiency in the face of high energy density and large capacity batteries. The direct cooling and direct heat testing machine realizes direct, efficient and uniform thermal management of the battery through advanced heat pipe technology.

The core principle of the direct-cooling direct-heat testing machine is to use the efficient thermal conductivity of the heat pipe to quickly conduct the heat generated by the battery to the condensing end of the heat pipe, and then exhaust the car through the cooling system; When heating is required, heat is extracted from the outside environment through heat pump technology and delivered directly to the heating end of the battery. This design not only greatly improves the heat dissipation efficiency of the battery, but also ensures the rapid preheating of the battery in extreme environments, thus significantly improving the performance and service life of the battery.

In practical applications, the direct-cold direct-heat testing machine has shown significant advantages. First of all, in a high temperature environment, it can effectively control the temperature rise of the battery to prevent the performance decline and safety risks caused by overheating of the battery. Secondly, in a cold environment, the direct-cold direct-heat test machine can quickly preheat the battery to ensure that the battery can still be charged and discharged normally at low temperatures, which greatly reduces the problem of reducing the range caused by low temperatures. In addition, the compact structure and light weight of the direct-cold direct-heat test machine are very suitable for the strict space and weight requirements of new energy vehicles.

The application of direct-cooling and direct-heating technology not only improves the performance and safety of the power battery of new energy vehicles, but also clears obstacles for the further development of new energy vehicles. In the future, with the continuous improvement and popularization of this technology, we have reason to believe that new energy vehicles will usher in a broader market prospect.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions