Automotive battery pack thermal management system temperature control technology competition: air cooling vs liquid cooling vs direct cooling

With the rapid development of electric vehicles, battery pack thermal management system has become one of the key technologies. The thermal management system is mainly responsible for temperature control of the battery to ensure that it operates within the appropriate operating temperature range, thereby improving the performance, safety and life of the battery. At present, the common battery pack thermal management technologies mainly include air cooling, liquid cooling and direct cooling. This paper will analyze the characteristics, advantages and disadvantages of these three temperature control technologies and their application scenarios in detail.

First, air cooling technology

Air-cooling technology uses natural or forced convection to blow air over the surface of the battery through a fan, taking away the heat generated by the battery. This technology has the advantages of simple structure, low cost and convenient maintenance. However, the heat dissipation effect of air-cooled technology is relatively poor, and it is difficult to meet the thermal management needs of high energy density batteries. Therefore, air cooling technology is mainly suitable for low energy density, small capacity batteries or other auxiliary heat dissipation methods.

Two, liquid cooling technology

The liquid cooling technology introduces the coolant into the battery pack through the liquid circulation system, which is in direct or indirect contact with the battery, absorbing and taking away the heat generated by the battery. Compared with air cooling technology, liquid cooling technology has the advantages of good heat dissipation effect and high temperature control precision. In addition, the liquid cooling system can also achieve precise control of the internal temperature of the battery pack by adjusting the coolant flow and temperature. However, the high cost of liquid cooling technology and the need for additional liquid circulation systems and sealing structures increase the complexity and maintenance of the system. Liquid cooling technology is suitable for high energy density, large capacity batteries, and scenarios requiring high safety and performance.

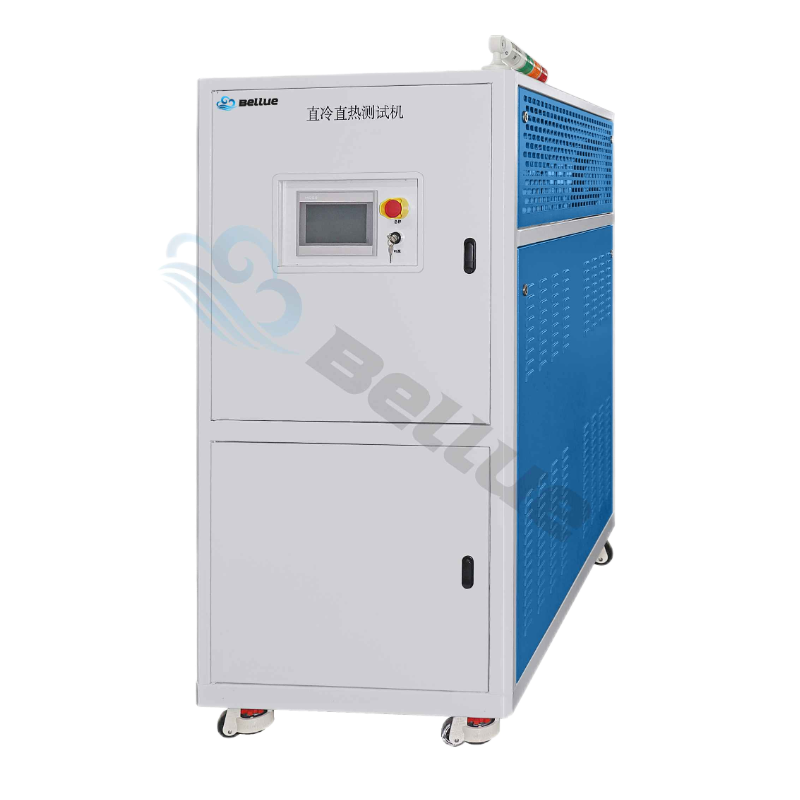

Third, direct cooling technology

Direct cooling technology is a technology that uses refrigerant to cool the battery directly. It absorbs the heat generated by the battery through the evaporation process of the refrigerant in the evaporator, and then compresses the refrigerant into high temperature and high pressure gas through the compressor, and then releases the heat to the external environment through the condenser. Direct cooling technology has the advantages of good heat dissipation effect, high temperature control precision and compact structure. However, direct cooling technology is more expensive and requires additional refrigeration systems and sealing structures, increasing the complexity and energy consumption of the system. In addition, direct cooling technology also faces potential risks such as refrigerant leakage and environmental pollution. Therefore, direct cooling technology is mainly suitable for scenarios with high battery performance and safety requirements, such as high-performance electric vehicles and electric buses.

In summary, air cooling, liquid cooling and direct cooling technologies have advantages and disadvantages and are suitable for different scenarios. When selecting a battery pack thermal management system, factors such as battery performance, safety, cost, and maintenance difficulty should be considered comprehensively to select the appropriate temperature control technology. With the continuous development of the electric vehicle market and the continuous progress of battery technology, the future battery pack thermal management system will develop in the direction of more efficient, more environmentally friendly and more intelligent.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions