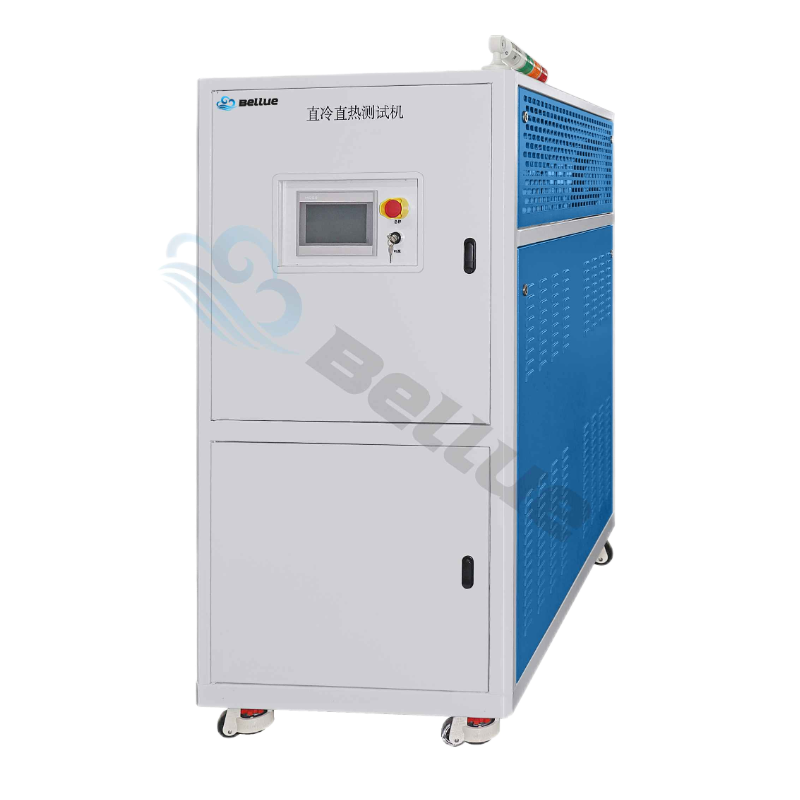

Analysis on the reason of cooling capacity decline of Freon direct cooling test machine

Freon direct cooling testing machine is widely used in refrigeration industry, its performance directly affects the refrigeration effect and product quality. However, in the actual use of the process, it may encounter the problem of cooling capacity reduction, affecting the test accuracy and production efficiency. This paper will analyze the reasons for the decrease of refrigeration capacity of Freon direct cooling test machine, and put forward the corresponding solutions.

First, the common reasons for the decline of refrigeration capacity of Freon direct cooling test machine

Refrigerant leakage: Refrigerant leakage of freon direct cooling test machines is a common cause of cooling capacity reduction. Leakage may occur at pipe joints, valves, compressors and other components, resulting in a reduction of refrigerant in the system, which affects the cooling effect.

Compressor failure: Compressor is the core component of Freon direct cooling test machine, and its performance directly affects the cooling capacity. Compressor internal wear, poor seal and other reasons may lead to the compressor efficiency is reduced, so that the cooling capacity is reduced.

Condenser and evaporator scaling: During long-term use of condensers and evaporators, scaling may occur due to water quality problems, dust in the air and other reasons. Scaling will reduce the heat exchange efficiency and thus affect the cooling capacity.

Internal blockage of the system: Pipes, filters and other components inside the Freon direct cooling test machine system may be blocked due to impurities, oxides and other reasons. Clogging causes the flow of refrigerant to be blocked, which affects the cooling effect.

Control system failure: The control system of the Freon direct cooling test machine is responsible for monitoring and regulating the refrigeration process. The failure of the control system may cause the cooling capacity to not be accurately controlled, and thus reduce the cooling capacity.

Second, measures to solve the cooling capacity decline of Freon direct cooling test machine

Regular inspection of refrigerant leakage: Regular inspection of pipes, valves, compressors and other components of Freon direct cooling test machine, and timely repair of leaks to ensure sufficient refrigerant in the system.

Maintain compressor performance: Maintain the compressor regularly and replace worn parts to ensure that the compressor is in good working condition.

Clean the condenser and evaporator: clean the condenser and evaporator regularly to remove scale and improve heat exchange efficiency.

Check and clean up the blockage inside the system: check the pipes, filters and other components inside the system regularly, and clean up the blockage in time to ensure the smooth flow of refrigerant.

Maintain and update the control system: The control system is inspected and maintained regularly to ensure that it accurately monitors and regulates the cooling process. If necessary, the control system can be updated to improve its performance.

In short, the reasons for the decrease of refrigeration capacity of freon direct cooling test machine may involve many aspects, which need to be comprehensively considered and corresponding measures should be taken to solve. Through regular inspection and maintenance, we can ensure that the Freon direct cooling test machine is in good working condition, improve the refrigeration effect and product quality.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions