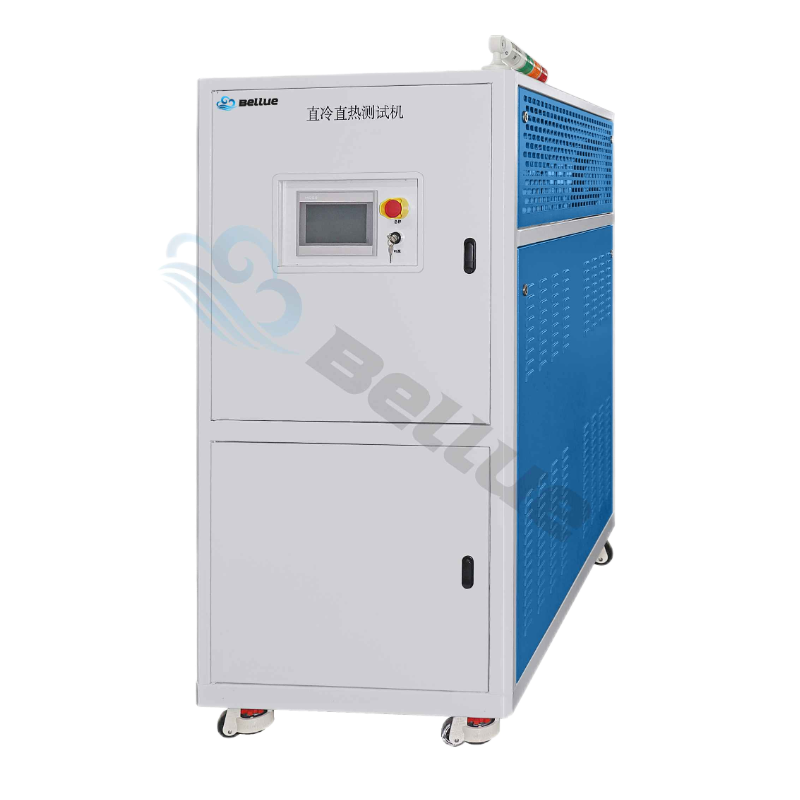

Product features and functions of Freon direct cooling battery pack test equipment

In today's surging new energy industry, battery pack as a core energy storage unit, its performance is directly related to the quality of the entire product and market competitiveness. In order to get a head start in this fierce competition, are you hungry for a device that can accurately test battery pack performance? Today, let's understand this industry-leading Freon direct cooling battery pack test equipment.

Product features and functions

1, direct cooling technology, better efficiency

Advanced freon direct cooling technology is used to achieve rapid and uniform cooling of the battery pack, ensuring the consistency of the battery temperature during the test process, and greatly improving the accuracy of the test data.

2, accurate control, impeccable performance

Equipped with high-precision temperature control system, it can simulate the working state of the battery pack in different temperature environments, and provide real and reliable data support for product development.

3, intelligent operation, easy to use

Humanized operation interface design, with intelligent control system, so that operators even without a deep professional background can easily get started.

4, safe and reliable, trustworthy

Multiple safety protection measures to ensure that the test process is safe and worry-free, effectively ensure the personal safety of the operator and the long-term stable operation of the equipment.

Product advantage and value

1. Improve research and development efficiency

With excellent cooling performance and accurate temperature control, the test cycle of the battery pack is greatly shortened, helping enterprises to respond quickly to market demand.

2. Reduce operating costs

The intelligent operating system reduces the manpower input, and the efficient working mode reduces the energy consumption, thus saving a lot of operating costs for the enterprise.

3. Enhance market competitiveness

Having this test equipment means that your product has more advantages in performance and can stand out in the fierce market competition.

Energy storage liquid cooling temperature control technology application advantages

How to derive the test results of high and low temperature coolant tester

High and low temperature coolant test electrical source circuit connection method

The problem of water source during the use of high and low temperature coolant testing machine

Coolant filling and discharging method of battery module high and low temperature liquid cooling test machine

High and low temperature liquid cooling test machine solutions